Bradsc1989

Plastic

- Joined

- Apr 1, 2023

this is A very specific question so I may not get an answer but figured it wouldnt hurt to ask.

I have the Mitutoyo 511-931-20 dial bore gage set. I was looking to pick up a setting fixture but didn’t really want to spend almost $2k on the mitutoyo fixture. I saw that both starrett and Fowler have one that’s more in my price range. In the photos of each fixture it shows a bore gage with the wheels like my Mitutoyo has. My concern is that there is a difference in some dimensional difference in the wheels themselves or the way they are arranged on the tool causing it to not be accurate. Any one have any useful insight?

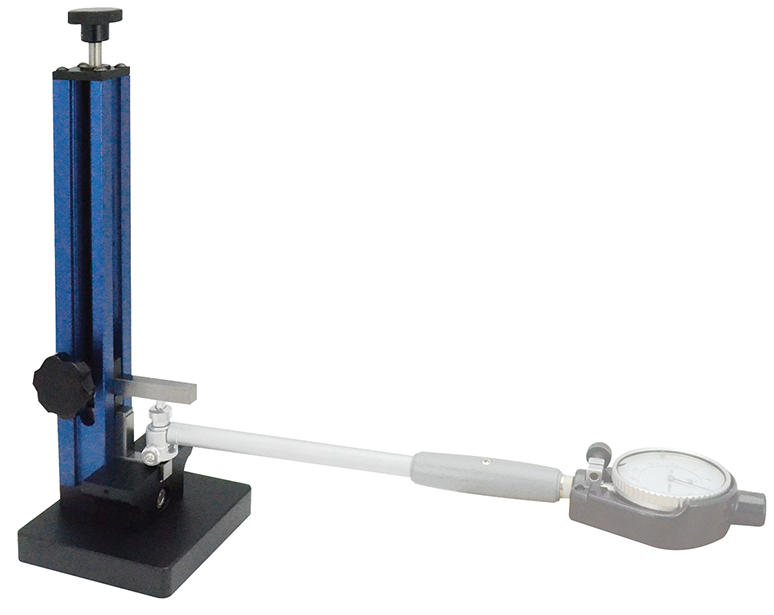

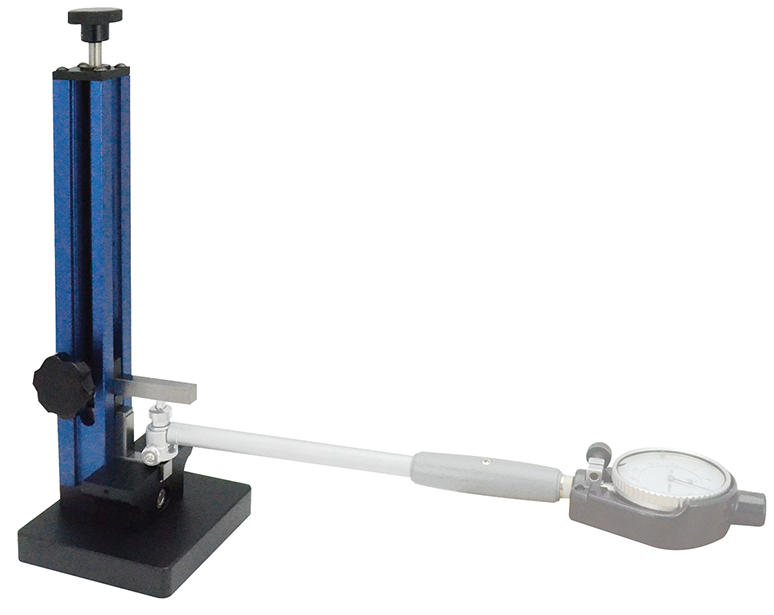

the setting fixtures I had in mind:

I have the Mitutoyo 511-931-20 dial bore gage set. I was looking to pick up a setting fixture but didn’t really want to spend almost $2k on the mitutoyo fixture. I saw that both starrett and Fowler have one that’s more in my price range. In the photos of each fixture it shows a bore gage with the wheels like my Mitutoyo has. My concern is that there is a difference in some dimensional difference in the wheels themselves or the way they are arranged on the tool causing it to not be accurate. Any one have any useful insight?

the setting fixtures I had in mind:

Fowler - Bore Gage Setting Master Kit - 53-646-000-1 | Judge Tool & Gage

Shop Fowler - Bore Gage Setting Master Kit - 53-646-000-1 from Judge Tool & Gage, trusted by the world's leading manufacturers, engineers, & designers.

www.judgetool.com

Starrett - Bore Gage Setter - 0 - 6" Range - w/ 36pc. Gage Block Set - 3089-RS36B | Judge Tool & Gage

Shop Starrett - Bore Gage Setter - 0 - 6" Range - w/ 36pc. Gage Block Set - 3089-RS36B from Judge Tool & Gage, trusted by the world's leading manufacturers, engineers, & designers.

www.judgetool.com