I'm looking to buy a small cyl grind for various pet projects I've got. I would like to do internal, external and tapers. Up to 10" swing and 15-20" cenetrs ( could be less). Could anybody advise what would be a versatile machine, lightish in weight, re-buildable and easy to use by a moron like me.

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cylindrical grinder advice needed

- Thread starter AlexO

- Start date

- Replies 34

- Views 5,107

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

Older Brown & Sharpe #1 Universal. Up until late forties they were still mechanical table traverse, so no hydraulics to nurse.

These are tool room machines - swiveling workhead, swiveling wheel slide. Both chucking and between centers capability.

John

These are tool room machines - swiveling workhead, swiveling wheel slide. Both chucking and between centers capability.

John

JRIowa

Diamond

- Joined

- May 27, 2003

- Location

- Marshalltown, Iowa, USA

IMHO, the best small universal is a Landis 1R. They had a 10" swing with 24" between centers. Most had an 80mm spindle (3.125") ID attachment.

I've seen them go for $2-15K USD depending on condition.

JR

I've seen them go for $2-15K USD depending on condition.

JR

SIP6A

Titanium

- Joined

- May 29, 2003

- Location

- Temperance, Michigan

Another machine to consider would be a Brown & Sharpe #13 it's classed as a tool & Cutter grinder but can be set up to do ID OD and surface grinding as well as tool and cutter grinding.

Spud

Diamond

- Joined

- Jan 12, 2006

- Location

- Brookfield, Wisconsin

How light is 'lightish'?

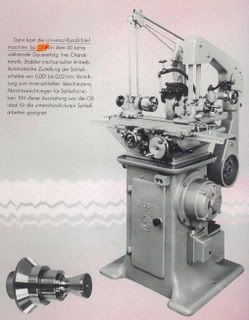

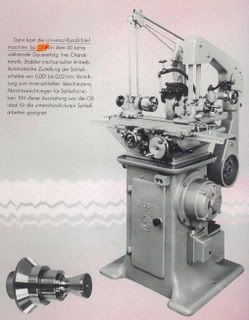

I got the below Studer OB universal internal/external cylindrical grinder.Even this 'smallish' looking machine is over 700 kilos with the base included.

Anglo-Swiss tools of England has glowing remarks for this machine as versatile.He mentions that the Swiss work holding Mfg GEPY uses these in their production.Mine was bought from an English Aerospace MFG who was using it until early last year when they got in new CNC machines to replace it.

http://www.anglo-swiss-tools.co.uk/StuderOB.html

I got the below Studer OB universal internal/external cylindrical grinder.Even this 'smallish' looking machine is over 700 kilos with the base included.

Anglo-Swiss tools of England has glowing remarks for this machine as versatile.He mentions that the Swiss work holding Mfg GEPY uses these in their production.Mine was bought from an English Aerospace MFG who was using it until early last year when they got in new CNC machines to replace it.

http://www.anglo-swiss-tools.co.uk/StuderOB.html

SIP6A

Titanium

- Joined

- May 29, 2003

- Location

- Temperance, Michigan

Spud:

That is the ultimate small OD ID grinder. Is yours the one John W had?

That is the ultimate small OD ID grinder. Is yours the one John W had?

Spud

Diamond

- Joined

- Jan 12, 2006

- Location

- Brookfield, Wisconsin

SIP6A

I bought mine in England via UK Ebay.The company was called Middlesex group.They manufacture all kinds of Aerospace stuff.While I was there they had a helicopter roter forging sitting on the table, cost 75,000 pounds to make.They make stuff for Boeing,Westland,British Aerospace,Rolls Royce,Ford and many more .

I got my Studer for about 185ish dollars but it cost me about 4000 dollars to go pick it up.Looong story and don't want to hijack the OP's post.

The machine is still in London with my firend but I got the manual here, its got a lot of technical info and a couple of pics.Machine is complete and great condition albeit caked with grinding swarf.

The company had 2 identical machines, they threw 1 away into the skip (dumpster).That happened before I got there.1 of the employess listed the 2nd (the one I bought)on Ebay. I was aghast when I heard they threw the first one, they said it was taking space.They are concerned with productivity and spent 1.5 million pounds on machines in 2006 so this was nothing for them.

I bought mine in England via UK Ebay.The company was called Middlesex group.They manufacture all kinds of Aerospace stuff.While I was there they had a helicopter roter forging sitting on the table, cost 75,000 pounds to make.They make stuff for Boeing,Westland,British Aerospace,Rolls Royce,Ford and many more .

I got my Studer for about 185ish dollars but it cost me about 4000 dollars to go pick it up.Looong story and don't want to hijack the OP's post.

The machine is still in London with my firend but I got the manual here, its got a lot of technical info and a couple of pics.Machine is complete and great condition albeit caked with grinding swarf.

The company had 2 identical machines, they threw 1 away into the skip (dumpster).That happened before I got there.1 of the employess listed the 2nd (the one I bought)on Ebay. I was aghast when I heard they threw the first one, they said it was taking space.They are concerned with productivity and spent 1.5 million pounds on machines in 2006 so this was nothing for them.

pepo

Hot Rolled

- Joined

- May 28, 2005

- Location

- phoenix,az usa

Landis 10 x 20 type 1R. These are great toolroom machines,well designed and set up quick.

Machinery_E

Titanium

- Joined

- Aug 19, 2004

- Location

- Ohio, USA

Okay, another vote for a Landis!!!! I've got a 2R (A little bigger at 14X36) its an awesome piece of machinery...  Landis is to a universal grinder, as Monarch is to a lathe, as Cincinnati is to a mill, etc.

Landis is to a universal grinder, as Monarch is to a lathe, as Cincinnati is to a mill, etc.

Eric

Landis is to a universal grinder, as Monarch is to a lathe, as Cincinnati is to a mill, etc.

Landis is to a universal grinder, as Monarch is to a lathe, as Cincinnati is to a mill, etc.

Eric

Although Myford is known in the USA more for light duty antique design bench lathes, they actually made a pretty nice little cylindrical grinder, the MG-12. Available in various configurations, from manual to fully automatic, with and without internal attachment.

It's possible Myford is still making these to this day, so spare parts should be available.

As to your other requirements, these require some mind reading abilities as I have no idea what you mean by "lightish" without putting an actual figure on it, and need some I.Q. figures to determine the "moron" aspects

It's possible Myford is still making these to this day, so spare parts should be available.

As to your other requirements, these require some mind reading abilities as I have no idea what you mean by "lightish" without putting an actual figure on it, and need some I.Q. figures to determine the "moron" aspects

"lightish" would be around 500Kg. As to moron that's a bit more difficult to explain. Let me try : seen 'em all in supervisory capacity, done some and at present will once a week start my lathe. The only machine I'm a heavy user of is a shaper - I'm a shaper maniac.

Actualy your ideea is great - Myford might be the ticket. I'm going to look for one.

Actualy your ideea is great - Myford might be the ticket. I'm going to look for one.

Machinery_E

Titanium

- Joined

- Aug 19, 2004

- Location

- Ohio, USA

Even with 3 votes for a Landis?  Not sure what you mean by "rebuildable" but my Landis had seen quite a bit of use, and it splits "tenths". Finish is just fantastic. Remember the more mass you have in a grinding machine the better, yet a 1R isn't that bad. The Myfords I have seen are quite a bit more expensive than the Landis machines.

Not sure what you mean by "rebuildable" but my Landis had seen quite a bit of use, and it splits "tenths". Finish is just fantastic. Remember the more mass you have in a grinding machine the better, yet a 1R isn't that bad. The Myfords I have seen are quite a bit more expensive than the Landis machines.

Not sure what you mean by "rebuildable" but my Landis had seen quite a bit of use, and it splits "tenths". Finish is just fantastic. Remember the more mass you have in a grinding machine the better, yet a 1R isn't that bad. The Myfords I have seen are quite a bit more expensive than the Landis machines.

Not sure what you mean by "rebuildable" but my Landis had seen quite a bit of use, and it splits "tenths". Finish is just fantastic. Remember the more mass you have in a grinding machine the better, yet a 1R isn't that bad. The Myfords I have seen are quite a bit more expensive than the Landis machines.FWIW, the Myford weighs about 950 kg...about the same as a Bridgeport mill. And M.E. is right, the Myfords are pricey...tend to sell for around $10,000 and up for a clean modern one, but older uglier one's show up on occasion in the $3,500 range.

Machinery_E

Titanium

- Joined

- Aug 19, 2004

- Location

- Ohio, USA

Okay-now that D. has probabley scared you off pricewise, look at this one-couldn't get a bid at $250! Sure, it might have issues by the looks of it, but for that price you could throw it in the scrap and still be okay!

Cheap Landis

Cheap Landis

Actualy he didn't. I would pay top price for a decent machine. There is a small Deckel cyl grinder and I asked a dealer in Germany to look for one. As a matter of curiosity I saw some years ago a home built cyl grinder based on a weird looking russian lathe. I wonder if anybody else attempted to build one.

Spud

Diamond

- Joined

- Jan 12, 2006

- Location

- Brookfield, Wisconsin

Deckel made a cylindrical grinder?There is a small Deckel cyl grinder and I asked a dealer in Germany to look for one

Do you mean tool & cutter grinder?

They did. Deckel made quite a bit of short series stuff for the german market. Specialized equipment for special clients. However my vote for this goes to TOS. Lots of "prototypes". This was normal for european manuf in the 50s and 60s. As a matter of curiosity there was a shaper still made in Germany in the late 80s and Deckel FP2LB were still available new some 5 years ago.

Spud

Diamond

- Joined

- Jan 12, 2006

- Location

- Brookfield, Wisconsin

AlexO

Can you post some pictures?Also any more info on that Shaper?

Thanks

Can you post some pictures?Also any more info on that Shaper?

Thanks

Similar threads

- Replies

- 0

- Views

- 114

- Replies

- 10

- Views

- 411

- Replies

- 19

- Views

- 2K

- Replies

- 124

- Views

- 5K