Hi all, I've recently joined a company who's in the automotive industry, and I'm on a drastic learning curve with all the specs that are out there.

I've received a drawing for a standard Grade 12 DIN 267 M24 x 3 Nut... apparently buying them off the shelf and shipping them off isn't how its done and I need to figure out how to make them.

I've struggled like hell with this request, nobody seems to really know how to reach the grade 12 spec for a nut and has just been as vague as " heat treat some alloy steel ".

I've contacted steel suppliers and asked for materials that meet spec and still have no clue.

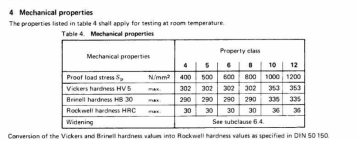

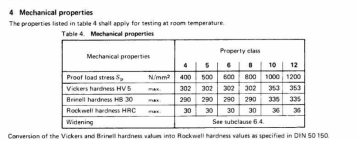

What I've found is that the Grade 12 requires a very high Proof load stress (min 1200 n/mm) which google tells me is similar to tensile strength but usually slightly lower, but also requires a moderate HRC and HB value.

I can't get my head round how you're supposed to hit over 1200 tensile strength without going over the max HB of 355 , or max HRC of 36. I really must be missing something.

Can anybody shed light on this subject? I'm going to need this information moving forward and don't want to wing it. Thus far I've been pointed in the direction of using 42CrMo4 or EN24 and tempering to a harder state, but then some of the values go over there max to reach the required tensile strength?

Any help on this would be greatly appreciated!!!!!

Thank you.

I've received a drawing for a standard Grade 12 DIN 267 M24 x 3 Nut... apparently buying them off the shelf and shipping them off isn't how its done and I need to figure out how to make them.

I've struggled like hell with this request, nobody seems to really know how to reach the grade 12 spec for a nut and has just been as vague as " heat treat some alloy steel ".

I've contacted steel suppliers and asked for materials that meet spec and still have no clue.

What I've found is that the Grade 12 requires a very high Proof load stress (min 1200 n/mm) which google tells me is similar to tensile strength but usually slightly lower, but also requires a moderate HRC and HB value.

I can't get my head round how you're supposed to hit over 1200 tensile strength without going over the max HB of 355 , or max HRC of 36. I really must be missing something.

Can anybody shed light on this subject? I'm going to need this information moving forward and don't want to wing it. Thus far I've been pointed in the direction of using 42CrMo4 or EN24 and tempering to a harder state, but then some of the values go over there max to reach the required tensile strength?

Any help on this would be greatly appreciated!!!!!

Thank you.