SeanShanny

Aluminum

- Joined

- Nov 17, 2021

- Location

- Shaftsbury, Vermont

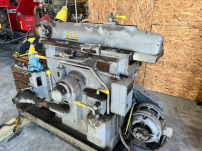

I am picking up a Gould and Eberhardt 20-24" Industrial Universal Shaper on Tuesday morning. When I have a serial number I would like to know approximately when it was manufactured if a forum member has access to that sort of info.

Also there are a few things missing and would appreciate any leads on the following:

Armstrong No. 42 tool holder. Seems rare as hens teeth.

A shaper vise. I have seen a couple of large vises on eBay but I need to confirm t slot spacing on my machine.

The rear way tray. I am guessing I will end up having to make one of these but I figured it would be worth a try to see if anyone has one or has pictures and dimensions.

Everything else appears to be there.

Plans are to clean, inspect, repair as needed, put into service in my shop. I will post picture and progress on this thread.

Thanks for any leads or advice.

--sean

Also there are a few things missing and would appreciate any leads on the following:

Armstrong No. 42 tool holder. Seems rare as hens teeth.

A shaper vise. I have seen a couple of large vises on eBay but I need to confirm t slot spacing on my machine.

The rear way tray. I am guessing I will end up having to make one of these but I figured it would be worth a try to see if anyone has one or has pictures and dimensions.

Everything else appears to be there.

Plans are to clean, inspect, repair as needed, put into service in my shop. I will post picture and progress on this thread.

Thanks for any leads or advice.

--sean