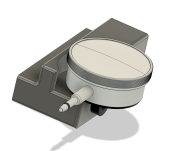

I want to make myself a dial indicator holder. Something like this build from Clough42 channel:

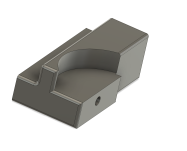

I'm lazy and short of time, so I was wondering about 3D printing it. I use Multifix tool posts on both my lathes, so I either 3D print the whole holder or I print a smaller piece that holds a dial indicator, but is supposed to be used with an existing multifix holder. The latter will probably live longer at a cost of using an existing tool holder for it.

What I'm wondering about is - do you think there would be any accuracy problems with a 3d printed holder? There will be no pressure from usage alone, no coolant while measuring either. Plastic will obviously move much more than metal, but the stress from using it is probably too small to affect the reading. I also don't think heat expansion would affect it much. Anything I missed or I'm wrong about? Anything else to take into account?

I'm lazy and short of time, so I was wondering about 3D printing it. I use Multifix tool posts on both my lathes, so I either 3D print the whole holder or I print a smaller piece that holds a dial indicator, but is supposed to be used with an existing multifix holder. The latter will probably live longer at a cost of using an existing tool holder for it.

What I'm wondering about is - do you think there would be any accuracy problems with a 3d printed holder? There will be no pressure from usage alone, no coolant while measuring either. Plastic will obviously move much more than metal, but the stress from using it is probably too small to affect the reading. I also don't think heat expansion would affect it much. Anything I missed or I'm wrong about? Anything else to take into account?