How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mitsubishi facemill cloudy finish in 6061.

- Thread starter empower

- Start date

- Replies 63

- Views 2,853

5 axis Fidia guy

Stainless

- Joined

- Aug 17, 2006

- Location

- Wisconsin

I personally would use coated and polished inserts for aluminum, only NOT the diamond coated.

i do believe 6061 is aluminumDiamond coated inserts are for Aluminum and composites only, or I should say, non ferrous materials.

5 axis Fidia guy

Stainless

- Joined

- Aug 17, 2006

- Location

- Wisconsin

I changed my response since I did not see what material he was using.i do believe 6061 is aluminum

why not DLC?I personally would use coated and polished inserts for aluminum, only NOT the diamond coated.

Houdini

Titanium

- Joined

- Nov 28, 2017

I don't know man, I get some bars from Kaiser as we all do, then I got some from a local Provo Utah manufacturer, and I gotta say that shite aient T6511i do believe 6061 is aluminum

The Provo stuff in the lathe actually breaks a chip easy, like its harder almost 7075.

Just spit on it, or rub some dirt on it, if that doesn't work WD40!

Orange Vise

Titanium

- Joined

- Feb 10, 2012

- Location

- California

I use the TF15 (uncoated, polished) grade.

gkoenig

Titanium

- Joined

- Mar 31, 2013

- Location

- Portland, OR

Agree with going unpolished insert or PCD if you wanna make the mirrors.

gregormarwick

Diamond

- Joined

- Feb 7, 2007

- Location

- Aberdeen, UK

I don't have that exact tool but I use Sandvik R790 which is more or less equivalent, and I use uncoated and unpolished inserts and get beautiful finishes in 6082-T6 pretty much regardless of how fast I spin it.

Wsurfer

Cast Iron

- Joined

- Apr 1, 2013

- Location

- Austin Texas

i have not, worth a shot!Just as a test, have you tried going back over the surface at the same height, no retract, no Z changes, just forward and back.

I have seen this work also, usually on dry, but sill, worth a try.

5 axis Fidia guy

Stainless

- Joined

- Aug 17, 2006

- Location

- Wisconsin

You can have coated inserts for aluminum that are polished, and you can have plain micrograin carbide inserts that are just polished, no coating.What? polished inserts aren't coated, its either coated or polished?

Not coated and polished, that's an oxymoron?

Houdini

Titanium

- Joined

- Nov 28, 2017

OK, I don't think I've ever seen a coated and polished insert, I'll take your word for it.You can have coated inserts for aluminum that are polished, and you can have plain micrograin carbide inserts that are just polished, no coating.

Every coated insert I've seen isn't polished, it's either or.

5 axis Fidia guy

Stainless

- Joined

- Aug 17, 2006

- Location

- Wisconsin

Diamond coatings are best used for abrasive materials and extremely long tool life, not necessarily a great surface finish. I tried a Diamond ball endmill in aluminum for finishing a mold core once, ( By the manufactures suggestion) and I got nowhere near the surface finish as I would have using a coated carbide tool meant for aluminum. We keep all our diamond tooling for cutting carbon electrodes and that's it.why not DLC?

gregormarwick

Diamond

- Joined

- Feb 7, 2007

- Location

- Aberdeen, UK

DLC and PCD are for tool life.

MCD inserts are the ultimate solution for surface finish, but I've only tried them in a turning application. Not sure how commonly available they are for milling?

MCD inserts are the ultimate solution for surface finish, but I've only tried them in a turning application. Not sure how commonly available they are for milling?

gregormarwick

Diamond

- Joined

- Feb 7, 2007

- Location

- Aberdeen, UK

definitely room to dial it in a bit more, but huge difference already.

guess those DLC inserts arent worth the ~$40 each that they're selling them for...

I'd definitely try unpolished while you're experimenting. I'd like to imagine the polishing is done before grinding the edge but if not then the unpolished will be sharper.

Polishing is supposed to prevent chip welding, but IME it doesn't make much difference.

Houdini

Titanium

- Joined

- Nov 28, 2017

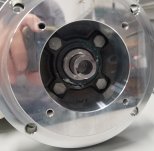

Oh, I didn't look up the inserts you were using, I assumed polished.so i got the same insert, just in TF15 grade which i believe is just polished.

24k rpm 100 ipm. .01" on finish pass

View attachment 424109

View attachment 424110

definitely room to dial it in a bit more, but huge difference already.

guess those DLC inserts arent worth the ~$40 each that they're selling them for...

yeah no DLC(no coatings).

Best finishes I have seen for Aluminium are either polished with no coating(coating is an oxymoron to me on a polished insert)

or even better finish I have seen is the ones with PCD with a PCD wiper.

Similar threads

- Replies

- 22

- Views

- 14K