Valvguy1

Plastic

- Joined

- Mar 23, 2024

- Location

- Baton Rouge, LA

I bought this lathe on an online auction. So far nobody can tell me the Motor Specs. I do know - it was "Born On" March 16th, 1944 and shipped to the McDonald Douglass Corp in Los Angeles. Between then and now it spent some amount of time in the Medford School District in Oregon. How it ended up here in Louisiana - I have no idea.

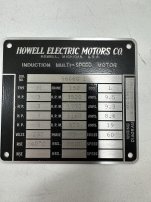

The Motor is a 4 speed 450, 900, 1200, 1800. Like all Oliver 25 Models -It is a Direct Motor Drive Unit. I suspect that it is 220 3 phase - but I can't confirm that yet. When I apply 220 VAC 3 Phase I hear a hum when I het the start button and nothing else. No Contactors move, etc. I'm pretty sure it is a 2HP since it has the 450 speed.

When I apply 220 VAC 3 Phase I hear a hum when I hit the start button - and nothing else. No Contactors move, etc. The amp draw is less than an amp on 2 legs and Zero on a third leg when the Start Button is depressed. I did manage to get the small contactor to close using a stream of compressed air. Still nothing. It did hum quite loudly and maintained contact. I haven't forced the larger contactor which is marked L1, L2, L3 and S closed when power is applied. On the large contactor I do have continuity on L1, L2 and L3 white wires when measured against wires with the same markings on the 3 220 legs heading into the machine. I do have 220 volt/Continuity across the Start Switch (NO?) when it is depressed. I have continuity across the Stop Switch at all times unless the Switch is depressed (NC?) I also see several components marked 440V 600V Maybe it is a 440 Machine.

Also, like all of these machines it has a mechanical interlock device so such that it can only be started on low speed. I have bypassed that and tried to start on all speeds. The Speed controller is Pull to Break Contact and Turn to change speed. Continuity works as expected

Attaching a few pics.

I'm hoping somebody can help. I did read somewhere that a VFD isn't going to make these contactors work. Maybe that is the issue?

The Motor is a 4 speed 450, 900, 1200, 1800. Like all Oliver 25 Models -It is a Direct Motor Drive Unit. I suspect that it is 220 3 phase - but I can't confirm that yet. When I apply 220 VAC 3 Phase I hear a hum when I het the start button and nothing else. No Contactors move, etc. I'm pretty sure it is a 2HP since it has the 450 speed.

When I apply 220 VAC 3 Phase I hear a hum when I hit the start button - and nothing else. No Contactors move, etc. The amp draw is less than an amp on 2 legs and Zero on a third leg when the Start Button is depressed. I did manage to get the small contactor to close using a stream of compressed air. Still nothing. It did hum quite loudly and maintained contact. I haven't forced the larger contactor which is marked L1, L2, L3 and S closed when power is applied. On the large contactor I do have continuity on L1, L2 and L3 white wires when measured against wires with the same markings on the 3 220 legs heading into the machine. I do have 220 volt/Continuity across the Start Switch (NO?) when it is depressed. I have continuity across the Stop Switch at all times unless the Switch is depressed (NC?) I also see several components marked 440V 600V Maybe it is a 440 Machine.

Also, like all of these machines it has a mechanical interlock device so such that it can only be started on low speed. I have bypassed that and tried to start on all speeds. The Speed controller is Pull to Break Contact and Turn to change speed. Continuity works as expected

Attaching a few pics.

I'm hoping somebody can help. I did read somewhere that a VFD isn't going to make these contactors work. Maybe that is the issue?