As suggested here, I contacted Tom Greer. He does have the adapter I need and it's priced at $350.00. I am pondering whether to bite the bullet and just buy it or keep looking. I also need to consider how often I turn between centers with this lathe which is not often.

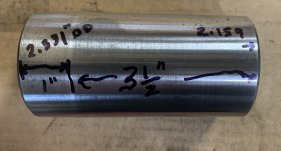

I thought I got lucky with Matt selling a 1:20 to MT4 spindle adapter. I jumped on it and sent payment. When I arrived home, I compared the measurements of my lathe and what Matt shows in his photos and much to my dismay, it's too big.

Matt being the gentleman he is, immediately refunded my money and I appreciate him accepting my apology.

I'm still on the hunt as I determine whether to buy the spindle adapter from Greer Machinery.

Many thanks to all who contributed and helped guide me, I do appreciate it.

Joe