Andrew Preisler

Plastic

- Joined

- Jan 8, 2024

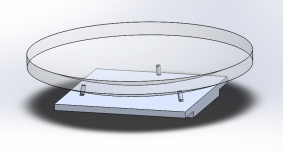

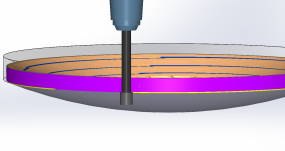

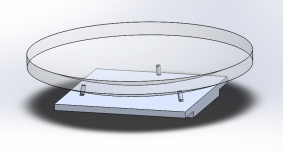

I have a large glass meniscus that I am trying to pregenerate a spherical radius into for conventional polishing using a vertical mill. This sucker is big, almost 13" OD. My fixture plan is to use the posts shown with some UV cure. In the image, I have the lens with the concave side up and alignment is not 100% critical as I pregenerate the curve; however, when the lens is flipped, how can I ensure that the optical axis is still oriented perpendicular to the spindle axis?

Quantities for this part are on the order of several hundred a year. So some kind of simple drop and place fixture for the operators would be perfect.

Quantities for this part are on the order of several hundred a year. So some kind of simple drop and place fixture for the operators would be perfect.