Hello

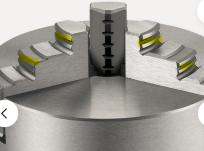

ive been at the lathe for many years making trumpet mouthpieces and trumpet parts. I just got a cheap Chinese 6 jaw chuck and it works pretty nice except for one weird thing.

its a set-tru and I easily dialed it in to .0003. The jaws feel like they positively Grab the material and give very repeatable runout of .0003.

when the work is spinning true, so is the chuck Body and the backing plate. What is NOT true is the outer edges of the jaws. When you look at the spinning chuck it’s VERY obvious that the side of the jaws facing out, opposite the work, are not at all swinging true. The wobble is maybe .010 or so. That seems like it must be unbalanced or somehow dangerous. The jaws are reversible two piece jaws.

the first thing I did was to check if the jaws were numbered and the slots were numbered. You can’t see the numbers until you take the jaw out, but they were in the right slots. is it possible the removable parts of the jaws are mixed up? I have not taken them off yet but don’t see any numbers. Should there be numbers? They must must be hidden if there are. Is it just possible that this whole scenario is more normal than I think? I’ve never had a 3 jaw look this weird spinning around. I have a video by the way

thanks for any help

ive been at the lathe for many years making trumpet mouthpieces and trumpet parts. I just got a cheap Chinese 6 jaw chuck and it works pretty nice except for one weird thing.

its a set-tru and I easily dialed it in to .0003. The jaws feel like they positively Grab the material and give very repeatable runout of .0003.

when the work is spinning true, so is the chuck Body and the backing plate. What is NOT true is the outer edges of the jaws. When you look at the spinning chuck it’s VERY obvious that the side of the jaws facing out, opposite the work, are not at all swinging true. The wobble is maybe .010 or so. That seems like it must be unbalanced or somehow dangerous. The jaws are reversible two piece jaws.

the first thing I did was to check if the jaws were numbered and the slots were numbered. You can’t see the numbers until you take the jaw out, but they were in the right slots. is it possible the removable parts of the jaws are mixed up? I have not taken them off yet but don’t see any numbers. Should there be numbers? They must must be hidden if there are. Is it just possible that this whole scenario is more normal than I think? I’ve never had a 3 jaw look this weird spinning around. I have a video by the way

thanks for any help