UptownSport

Cast Iron

- Joined

- Jul 25, 2012

- Location

- Cable WI

All's Well Then!

Happy New year!

Happy New year!

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

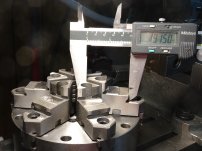

My 6 jaw doesn't do that.As it turns out, it is correct and normal. For removable/reversible two piece jaws to be able to run true on both the inner surface and and also when reversed, the top jaws have to be different lengths from the inner grabbing surface to the outer grabbing surface. And by kind of a lot. That dimension varies by .025.

I still have no clue what he's babbling on about, since it seems to be beyond world-class abilities to take a simple phone photo and put it in the thread ....My 6 jaw doesn't do that.

Post 13 has videos. It's strobing pretty badly due to the camera and lights but, when it stops, its a normal 6-jaw chuck with reversible jaws. I can't tell if this is a strobing effect from LED lights or it's really running out.I still have no clue what he's babbling on about, since it seems to be beyond world-class abilities to take a simple phone photo and put it in the thread ....

Whoop-dee-fucking doo. Dropbox does not work with older browsers. They can shove their site up their dripping ass.Post 13 has videos.

So how the hell is that supposed to work? Facing one way, the ends are concave. Facing the other they'd still be concave facing the wrong way. Or is he talking about just the pointy part, then holding onto a large bore ? Or does he just mean soft jaws ? wtf is he talking about ? When people get everything wrong, how can you deal with the question ? That's why a simple photo is necessary, because a lot of people don't have a clue what they are doing.eKretz said:His "reversible jaws" are simply two piece jaws where the top jaw unbolts and gets flipped 180°.

To demonstrate what RN meant, I took the time tonight to perform that test on two Pratt Burnerd and Chinese 6.3" 6-jaw chucks. I bought the PBI new several decades ago and the Chinese chuck is newer, but has never been mounted. The Chinese chuck is a close copy of a Buck and probably had a BTC brand thin round label that fell out of the round recess that just says "IA" (right side of an N and the A). The PBI chuck was quite expensive back then and still is. I found the China chuck on eBay for a relatively low price, but BTC chucks are not very cheap new. Note that PBI chucks have American standard tongue and groove 2-piece jaws, but Buck and the China copies have a Buck design that is only a Buck standard. The difference is important if you are shopping for soft top jaws or replacement hard top jaws.Measure between the inner face and outer face of each jaw with calipers, see what the range is.

Yep. We're all scratching our heads because something that should be easily measurable with a caliper is going on here. After watching an Adam Savage video where his lathe had the change gear knob installed wrong from all the way back to when it was built, I've learned anything could be wrong here. My suspicion is something numbered has the wrong number on it and it's in the wrong spot.He's mentioned in text that there's runout on the back side of the jaws when the front side of the jaws are running true.

Whoop-dee-fucking doo. Dropbox does not work with older browsers. They can shove their site up their dripping ass.

Golf clap for Larry. Well done sir! Why has this not been done by the OP?To demonstrate what RN meant, I took the time tonight to perform that test on two Pratt Burnerd and Chinese 6.3" 6-jaw chucks.

Whoop-dee-fucking doo. Dropbox does not work with older browsers. They can shove their site up their dripping ass.

Put the damn photo right here where people can see it. If you want to ask a question and have people bother to think and explain, make it halfway easy for them. Like I said, do people in the US have even one quarter of a brain anymore ?

Right here on this very website, when you write a reply, at the top, click "add photo" then drag it to the little box. Really really difficult. It can be an intelligence test, if you're too fucking stupid to do that, you don't deserve an answer.

So how the hell is that supposed to work? Facing one way, the ends are concave. Facing the other they'd still be concave facing the wrong way. Or is he talking about just the pointy part, then holding onto a large bore ? Or does he just mean soft jaws ? wtf is he talking about ? When people get everything wrong, how can you deal with the question ? That's why a simple photo is necessary, because a lot of people don't have a clue what they are doing.

Thanks, however I would not call those "modern". I'd call them "shitty".Most of the more modern hard two piece jaws that I've used have dual radii on the outside jaw steps.

Outsides on the female buck jaws are not ground, they don't touch anything, who cares ? Same with the outside edges of the id-holding bucks. I never measured them, because they touch air, and it doesn't matter.None of the 6 jaw chucks I've used had anywhere near .015"- .030" runout, anywhere.

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.