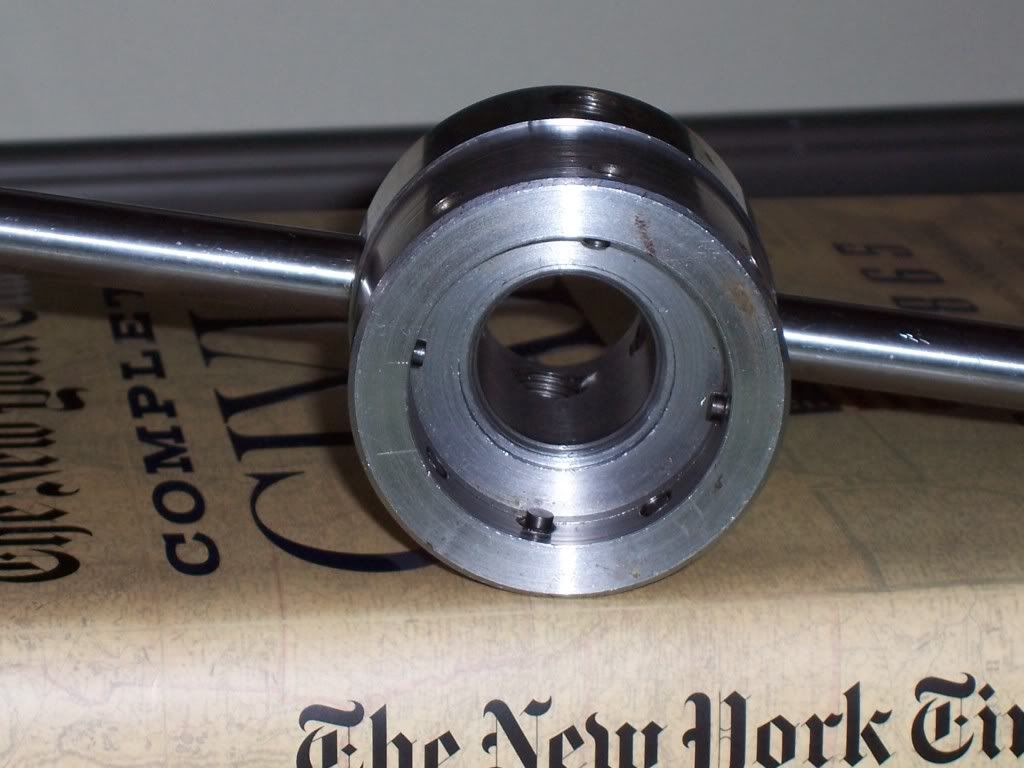

I'm sorry to hear of your flood. I don't know much about Bridgeports or the cost of bearings for them, but as to removing the nut, I will offer the following comments: 1. Make sure the lock tab is disengaged before trying to remove the nut. Sorry if this is dead obvious, but in the picture you provided, the lock seems to be engaged. 2. Make sure that you are applying force in the right direction. (Is this nut RH or LH thread?) Try tapping against one of the slots with a soft drift or pin punch, not a chisel. If that doesn't work, you may have to make a tool to remove the nut, or perhaps borrow something from a kindly member here who has one. That nut shouldn't be terribly tight and should respond to a reasonable amount of force to get it loosened.

As to the motor, I wouldn't worry too much about it, beyond the bearings probably needing replacement and perhaps the start switch needing to be cleaned. People make a big fuss over motors getting wet, especially the old ones with cloth insulation. I've never had a problem, and you probably won't either, so long as you get the motor thoroughly clean and dry before trying to run it. The motor will dry out better if you dry it while it's apart, and reassemble it once it's completely dry. Leave it near a heat outlet, or set it outside on a warm, sunny day. Do this for a couple of weeks or so and the motor will be dry and shouldn't give you any unpleasant surprises.

You are right that the single phase motor is of interest to home machinists and should be saved.

I had a basement flood the other year (clean water, the sump pump went on strike) and there was a cheap 20" box fan down there. Since the water didn't even trip any circuit breakers (110 and 220 outlets were under water!) I said what the heck and plugged in the dripping wet fan. It took off like new and blew a stream of water out the back. There were several other motors down there (boiler circulator pump, exhaust fan for the boiler, etc.) and all of them were immersed. None suffered any damage I could detect, although I didn't try to run them while wet (and don't recommend that anyone else try, either).

Steve