sprucetop1

Aluminum

- Joined

- Jan 27, 2009

- Location

- United Kingdom

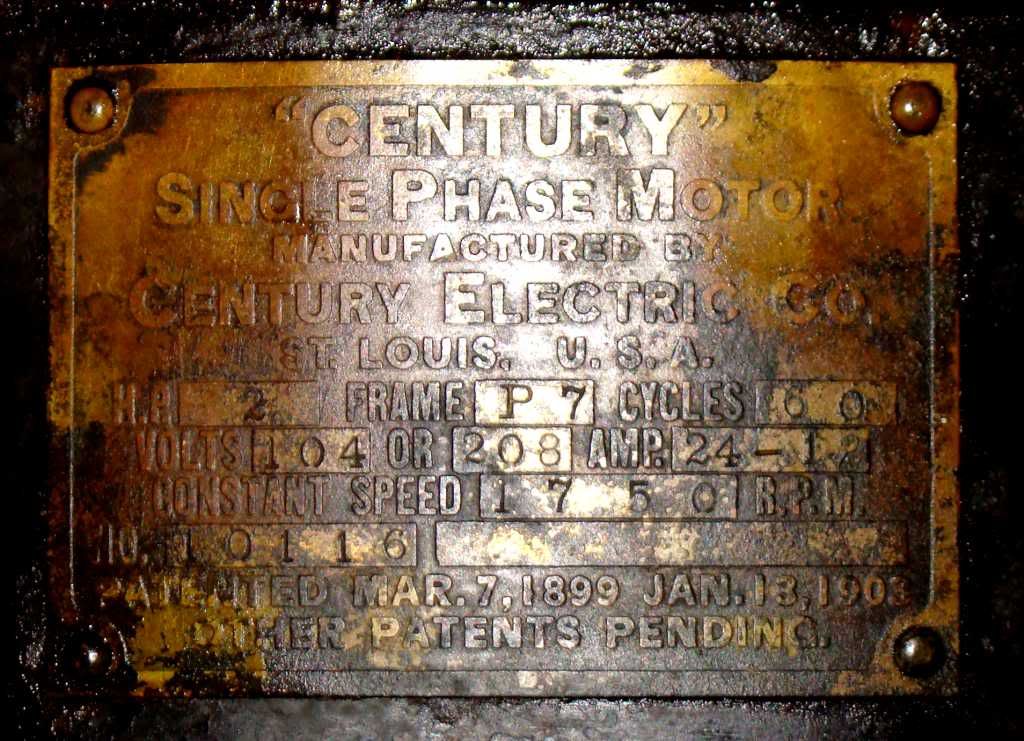

Bruce, thanks for info. on the Century motor on the 1937 era Savage nibbler that is similar to mine...any pix? The serial no on my motor is F923712 with the "37" in a bolder font....so maybe this is the year of manufacture? It was being used to power a 1920's lathe when I got it and the workshop had been there for at least 60 years, so a 1937 date seems reasonable.