Travismachine

Plastic

- Joined

- Mar 3, 2024

- Location

- Harriman, tn

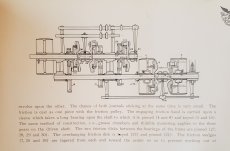

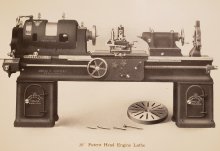

Hi guys I’m a newbie to the page, but I just bought a lodge and Shipley lathe 20” and I’m trying to find any info on it, diagrams mfg date. Operating manual. Really anything would be helpful I found the serial number which is 11691 with a patented date of April 10th 1984. She’s an old one but I think it will be a good one if I can tune her in right. Currently some of the gears on the manual feed and screw feed are broke off. So I’m trieng to find a diagram to make sure I’m not missing anything. I will include pics so maybe that will help. Thanks for any advice