Video_Man

Plastic

- Joined

- Mar 30, 2020

- Location

- South Florida

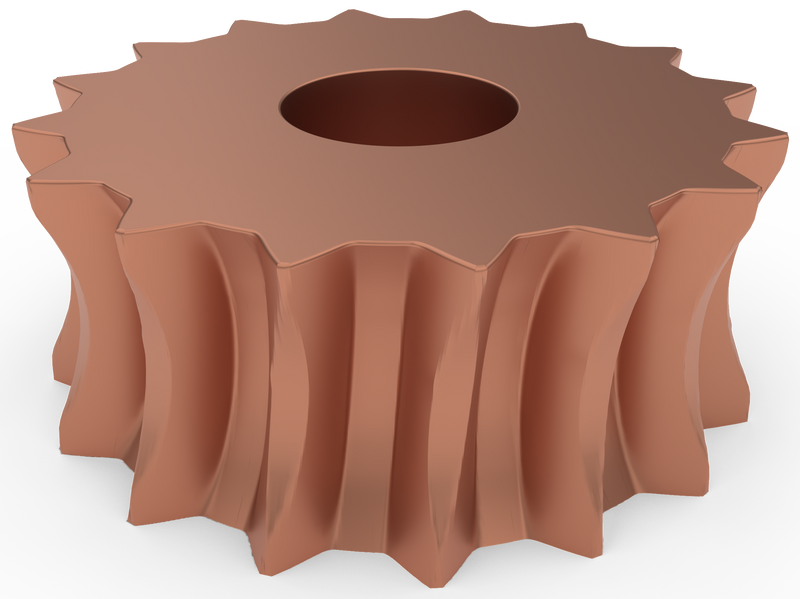

Ran into a similar problem. The OEM spur gear only touched the lead screw on the edges, and wore over time so that the index marks were out of synch. 3D printed a helical gear matching the screws helix, works just fine. Should the OP have a 3d printer I can modify my .stl file for him if he has an accurate lead screw diameter, pitch, and number of teeth on the gear.