jlegge

Stainless

- Joined

- Oct 7, 2004

- Location

- Grayslake, IL

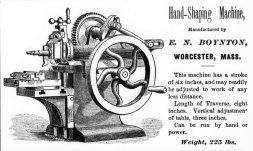

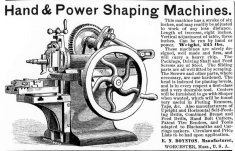

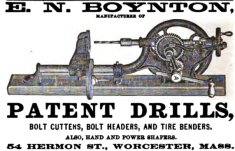

Just getting around to posting about the Boynton and Plummer shaper I picked up along with a Monarch Junior lathe (see post in the Monarch group). The best I can figure the shaper was made around 1900, maybe bit few years earlier. The larger flywheel has been removed and the electric motor pulley replaced it. It cuts surprising well for its age. Does anyone know why there is the hole in the back which cuts through the builder's name. It almost looks like it was cast in place, but it looks odd.