laurent12100

Aluminum

- Joined

- Sep 7, 2023

Hello,

OK Machine is in the shop

But I maybe need some help too start

the machine has been purchased by a dealer, he changed the spindle few years ago and machine was never sell (but I think some things missed)

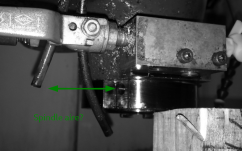

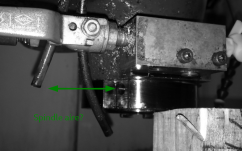

If someones can send me pictures of the spindle :

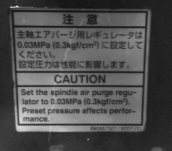

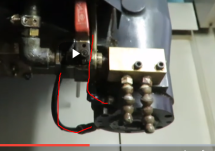

- I think air need to be connect for the spindle for tools and the second for chips

a cover is missing

- Z cover missing

- Pressure for water ?

- I don't have all keys : I have A but don't have B and C (I send mail to seller and local Brother company)

- I have ask brother Comm

- On BT30 is it 45° or 60° ?

thank you !

OK Machine is in the shop

But I maybe need some help too start

the machine has been purchased by a dealer, he changed the spindle few years ago and machine was never sell (but I think some things missed)

If someones can send me pictures of the spindle :

- I think air need to be connect for the spindle for tools and the second for chips

a cover is missing

- Z cover missing

- Pressure for water ?

- I don't have all keys : I have A but don't have B and C (I send mail to seller and local Brother company)

- I have ask brother Comm

- On BT30 is it 45° or 60° ?

thank you !