Romak

Aluminum

- Joined

- Nov 2, 2011

- Location

- Surrey, BC

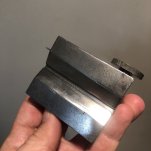

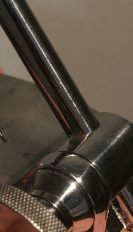

Dear machinists! I have this unusual all-metal attachment with a needle or a pointer and I believe it is from an antique or vintage lathe. Does anybody know what this is properly called and maybe for what type of machinery this attachment was designed for?

Thank you!

Thank you!