Ox

Diamond

- Joined

- Aug 27, 2002

- Location

- Northwest Ohio

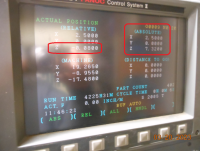

IDK what to make of this, but you are right!

It was 3.69, but ...

Good eye!

And I am sure that I had to of done it myself, not realizing that I was in WEAR at the time.

I mean - what's the odds that someone else had a tool with almost the same offset in just that pocket before we got the machine?

I know that I have dealt with this a few times now on set-ups, and I wouldn't have thought that I would have always been setting it up with T24, but I am now second guessing...

Typically I would touch off with a drill or C-drill, or something like that.

There were a few .005 - .015 values in WEAR as well, but not in pockets that I have used yet.

This mill has twin 20 tool changers, and I haven't used it much yet, so lots of open pockets in there yet!

Well, I am sure that this will clear up one issue...

Now I need to git a thumb drive reader hooked up to it...

Yeah, this thing has offsets to 400!

-------------------------

Think Snow Eh!

Ox

It was 3.69, but ...

Good eye!

And I am sure that I had to of done it myself, not realizing that I was in WEAR at the time.

I mean - what's the odds that someone else had a tool with almost the same offset in just that pocket before we got the machine?

I know that I have dealt with this a few times now on set-ups, and I wouldn't have thought that I would have always been setting it up with T24, but I am now second guessing...

Typically I would touch off with a drill or C-drill, or something like that.

There were a few .005 - .015 values in WEAR as well, but not in pockets that I have used yet.

This mill has twin 20 tool changers, and I haven't used it much yet, so lots of open pockets in there yet!

Well, I am sure that this will clear up one issue...

Now I need to git a thumb drive reader hooked up to it...

(none of my 0 controls have a wear page for offsets, only length; we use offsets 61+ for cutter comp offsets)

Yeah, this thing has offsets to 400!

-------------------------

Think Snow Eh!

Ox