dazz

Stainless

- Joined

- Aug 20, 2006

- Location

- New Zealand

Hi

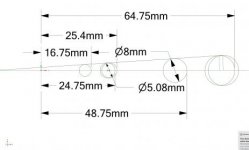

I purchased an imperial Mini Haimer 3D probe in new condition. It is identical to the image except it is missing the tip.

Replacement tips are available locally at about $USD137. I could import one from the USA or Europe but international shipping time is too slow and cost is too high.

I have looked at making a tip and found this YT video: Making a replacement Haimer Tip

but I don't have the remains of a broken tip to work with.

I am now looking at making a number of tips, and if I do that, I might as well make a range of different length tips. Then if I break one, I will have a replacement on hand. If I make a range of lengths, the gauge will be more versatile.

The first problem is my Haimer is imperial and came with a 0.20" ball.

I could start with a tooling ball but it would have much the same problems at an original Haimer tip plus being nearly the same price.

The next option is to start off with a SS ball bearing. 0.200" are unobtainable here but the nearest size is 5mm (0.197"). I can correct for that by adjusting the length of the tip.

So if I start with a 5mm SS304 ball (easy to get), the first thing I would need to do is make it look like a tooling ball. Drill a hole most of the way through and then insert a pin.

First Question: What would be the recommended method of attaching the pin to the ball. I am thinking of using Loctite.

The YT video uses a 3D printed tip base but I am not sure that will be good enough to be able to swap tips without recalibrating.

I see one of the advantages of making a range of tips is to swap tips of different lengths mid job. Maybe I am overthinking this.

I am thinking of using aluminium tip bases to help achieve uncalibrated tip swaps.

I know I will need to make a fixture that holds the tip base, graphite leads and ball in the correct relative positions.

The DIY approach will allow me to make tips for less than $1 plus time. Using different diameter balls will allow me to use a range of metric ball to give valid inch readings. Each size of ball will require the tip to be a different length, a good thing.

Second Question: Is there a better way?

Edit: The image attachments don't seem to be working.

Dazz

I purchased an imperial Mini Haimer 3D probe in new condition. It is identical to the image except it is missing the tip.

Replacement tips are available locally at about $USD137. I could import one from the USA or Europe but international shipping time is too slow and cost is too high.

I have looked at making a tip and found this YT video: Making a replacement Haimer Tip

but I don't have the remains of a broken tip to work with.

I am now looking at making a number of tips, and if I do that, I might as well make a range of different length tips. Then if I break one, I will have a replacement on hand. If I make a range of lengths, the gauge will be more versatile.

The first problem is my Haimer is imperial and came with a 0.20" ball.

I could start with a tooling ball but it would have much the same problems at an original Haimer tip plus being nearly the same price.

The next option is to start off with a SS ball bearing. 0.200" are unobtainable here but the nearest size is 5mm (0.197"). I can correct for that by adjusting the length of the tip.

So if I start with a 5mm SS304 ball (easy to get), the first thing I would need to do is make it look like a tooling ball. Drill a hole most of the way through and then insert a pin.

First Question: What would be the recommended method of attaching the pin to the ball. I am thinking of using Loctite.

The YT video uses a 3D printed tip base but I am not sure that will be good enough to be able to swap tips without recalibrating.

I see one of the advantages of making a range of tips is to swap tips of different lengths mid job. Maybe I am overthinking this.

I am thinking of using aluminium tip bases to help achieve uncalibrated tip swaps.

I know I will need to make a fixture that holds the tip base, graphite leads and ball in the correct relative positions.

The DIY approach will allow me to make tips for less than $1 plus time. Using different diameter balls will allow me to use a range of metric ball to give valid inch readings. Each size of ball will require the tip to be a different length, a good thing.

Second Question: Is there a better way?

Edit: The image attachments don't seem to be working.

Dazz