neanderthal mach

Hot Rolled

- Joined

- Dec 18, 2008

- Location

- princeton b.c.

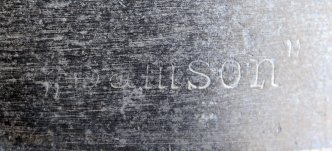

The part your asking about is normally referred to as a combined center and drive for a part rotated between the dividing heads foot stock, (same as a lathes tail stock, but called that different name) Since I don't know for sure what your dividing head uses for it's spindle taper, I can't say for sure the taper on your part does in fact fit the spindle taper. Make sure to clean the rust and dirt off that parts taper as well as the dividing heads internal spindle and try it for fit. There's a further part you'd need called a drive dog. It clamps onto the part and the leg of your drive dog fits into one of the slots in that part. This drive plate picture only has one slot but how it works is exactly the same.