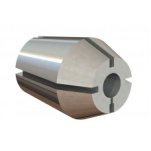

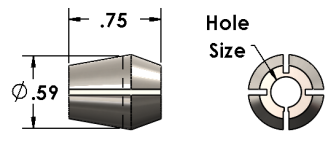

I picked this up used pretty cheap and I think I have the collets figured out but not sure on mounting this to my mill drill or my drill press specifically the drive pin for the unit. its an easy cheap way to increase consistency and speed things up. Collets seem hard to come by, looking for some decent sources but my google is being hampered by an aircraft of the same name that is much more popular. ;-)

Does anyone have a source for the collets, I am pretty sure they are the 375 collet type, or is there a replacement collet assembly that is newer and cheaper I would be better off getting and replacing the assembly.

Also any tips or sites for getting the clamps to fit the adapters. I can cut the pipe to make them just need a source for the cast clamps for the mill drill or drill press.

Thanks in advance, i'm small and working on getting production on some parts streamlined.

Does anyone have a source for the collets, I am pretty sure they are the 375 collet type, or is there a replacement collet assembly that is newer and cheaper I would be better off getting and replacing the assembly.

Also any tips or sites for getting the clamps to fit the adapters. I can cut the pipe to make them just need a source for the cast clamps for the mill drill or drill press.

Thanks in advance, i'm small and working on getting production on some parts streamlined.