Finngineering

Plastic

- Joined

- Oct 14, 2022

The new servos I got with the machine are:

X+Z (Maho): Leadshine ELM1000FM80H-SS, 3.18Nm @ 3000 rpm

Y (Maho): Leadshine ELM2000EM130F-H, 7.7Nm @ 2500 rpm

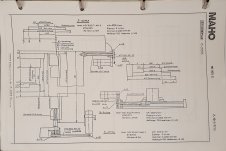

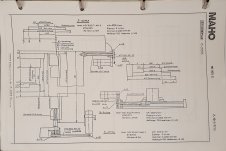

I got a (German) manual with the machine. The below pages are from that one. In the first you can see the "nominal" torque of the original motors, the transmission (gear) ratio and in the second one the adjustment instructions for the slip clutch.

So at least on paper, the torque of the new servos are on par with the original ones. Base on the original servo motor data sheet, I had a feeling that the original servos would have had more peak/dynamic torque. But based on the Y-axis (Maho) slip clutch setting, maybe not, . In fact, the Y-axis (Maho) transmission ratio is 1:3.27, so the 8 Nm "nominal" torque on the drawing would translate to 26 Nm, which would just barely cause the clutch to slip.

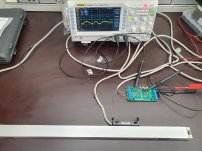

There are two things I don't like with the new servos. The rotational inertia is quite low for the X+Z (Maho) axes, which could lead to stability issues, and the drives for the same only accept step + dir inputs. The Y axis (Maho) drive accepts analog +-10V, which is what I would prefer. I have ordered a Mesa 7i95T card which uses step + dir, so that is what I will use. There is a risk that LinuxCNC would start trying to correct for a slightly incorrect position before the drive has even "commanded" the servo to move there. But others have apparently got it to work. I guess the closed control loop in LinuxCNC just needs to be slow enough that the servo/drive loop is faster.

X+Z (Maho): Leadshine ELM1000FM80H-SS, 3.18Nm @ 3000 rpm

Y (Maho): Leadshine ELM2000EM130F-H, 7.7Nm @ 2500 rpm

I got a (German) manual with the machine. The below pages are from that one. In the first you can see the "nominal" torque of the original motors, the transmission (gear) ratio and in the second one the adjustment instructions for the slip clutch.

So at least on paper, the torque of the new servos are on par with the original ones. Base on the original servo motor data sheet, I had a feeling that the original servos would have had more peak/dynamic torque. But based on the Y-axis (Maho) slip clutch setting, maybe not, . In fact, the Y-axis (Maho) transmission ratio is 1:3.27, so the 8 Nm "nominal" torque on the drawing would translate to 26 Nm, which would just barely cause the clutch to slip.

There are two things I don't like with the new servos. The rotational inertia is quite low for the X+Z (Maho) axes, which could lead to stability issues, and the drives for the same only accept step + dir inputs. The Y axis (Maho) drive accepts analog +-10V, which is what I would prefer. I have ordered a Mesa 7i95T card which uses step + dir, so that is what I will use. There is a risk that LinuxCNC would start trying to correct for a slightly incorrect position before the drive has even "commanded" the servo to move there. But others have apparently got it to work. I guess the closed control loop in LinuxCNC just needs to be slow enough that the servo/drive loop is faster.