Chevy427z

Stainless

- Joined

- Oct 12, 2004

- Location

- Clinton, North Carolina

Hi Folks.

I've been dealing with this ever since I was introduced to Fanuc controls years ago and just dealt with it, but decided that it's time to get the record set straight (in my mind anyhow). I know that it's been discussed in the past but I can't find those threads again.

My O-M is mounted on a mid 90s LeBlond-Makino 4 axis mill.

I set my tools by touching off on top of a 6" block which sits directly on the machine table. I input the relative position in the tool offsets. Then I use a dial indicator to find the difference from the top of the 6" block to the top of my part and input that difference into the G54 Z register.

The machine puts the tool exactly where it needs to be (in Z) but the on screen "position" is never correct.

If I touch off the tool directly on top of my part, input the relative position into the G54 Z register, and zero in the tool length offset, the machine puts the tool where it needs to be (in Z) and the absolute location shows properly on the "position" screen. Obviously, I can only do this with one tool, but would love to be able to get the same result with multiple tools. What am I missing or doing wrong?? Many thanks for looking!

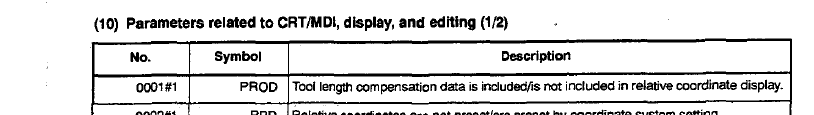

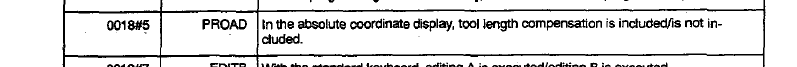

Edited: added some pictures incase someone recognizes an error in my math or methods.

Mark

I've been dealing with this ever since I was introduced to Fanuc controls years ago and just dealt with it, but decided that it's time to get the record set straight (in my mind anyhow). I know that it's been discussed in the past but I can't find those threads again.

My O-M is mounted on a mid 90s LeBlond-Makino 4 axis mill.

I set my tools by touching off on top of a 6" block which sits directly on the machine table. I input the relative position in the tool offsets. Then I use a dial indicator to find the difference from the top of the 6" block to the top of my part and input that difference into the G54 Z register.

The machine puts the tool exactly where it needs to be (in Z) but the on screen "position" is never correct.

If I touch off the tool directly on top of my part, input the relative position into the G54 Z register, and zero in the tool length offset, the machine puts the tool where it needs to be (in Z) and the absolute location shows properly on the "position" screen. Obviously, I can only do this with one tool, but would love to be able to get the same result with multiple tools. What am I missing or doing wrong?? Many thanks for looking!

Edited: added some pictures incase someone recognizes an error in my math or methods.

Mark

Attachments

Last edited: