Domodude17

Aluminum

- Joined

- Aug 14, 2017

So I have a Colchester Master Mk.2. It has a flanged shaft that bolts to the side of the headstock, and a pulley with some bearings pressed in slips onto the shaft. The pulley is what takes the power into the headstock. The shaft remains stationary, so the bearing inner race is fixed while the outer race rotates with the pulley.

When I got this lathe, the bearing races were all chewed up and the bearings were toast. I turned down the journal on a different lathe and pressed a sleeve on, and turned that sleeve to a press fit with the ID of the bearing. This caused too little clearance, and the bearings were getting excessively hot. There also wasn't a good way to install the pulley with a press or anything, so the pulley had to be hammered into place. After realizing the journal OD was the issue, I put it back on my other lathe and dusted off a few tenths to get it closer to a slip fit. I succeeded, and the pulley assembly can now slip over the shaft without much fanfare, but the inner race can spin just a tiny bit, and did so when the pulley was driven from the motor.

I REALLY don't want to press that repair sleeve off and turn a new one just a handful of tenths larger. The above work is the culmination of MONTHS of on and off work on this lathe, and I just want to be done with it. I'm just a home shop guy, and i've probably put more work and money into this lathe than I should have so I have been feeling a little disappointed.

I want to just use a bit of loctite on the bearing journal to hold them in place. The issue is that I don't have access to these bearings to apply heat or solvent should I need to remove this pulley in the future. Is there a type of "low strength" loctite that I might still be able to muscle off if needed using a bolt puller arrangement? Alternatively, the bearings are captured in the pulley on both sides by snap rings. I could leave off the snap ring on the righthand side, so that if I need to remove this pulley the pulley itself would slide off, leaving the bearings on the shaft where I can get some heat or solvent on them.

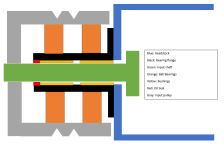

The attached photo shows the arrangement (minus the snap rings) on the left and right sides of the bearings.

When I got this lathe, the bearing races were all chewed up and the bearings were toast. I turned down the journal on a different lathe and pressed a sleeve on, and turned that sleeve to a press fit with the ID of the bearing. This caused too little clearance, and the bearings were getting excessively hot. There also wasn't a good way to install the pulley with a press or anything, so the pulley had to be hammered into place. After realizing the journal OD was the issue, I put it back on my other lathe and dusted off a few tenths to get it closer to a slip fit. I succeeded, and the pulley assembly can now slip over the shaft without much fanfare, but the inner race can spin just a tiny bit, and did so when the pulley was driven from the motor.

I REALLY don't want to press that repair sleeve off and turn a new one just a handful of tenths larger. The above work is the culmination of MONTHS of on and off work on this lathe, and I just want to be done with it. I'm just a home shop guy, and i've probably put more work and money into this lathe than I should have so I have been feeling a little disappointed.

I want to just use a bit of loctite on the bearing journal to hold them in place. The issue is that I don't have access to these bearings to apply heat or solvent should I need to remove this pulley in the future. Is there a type of "low strength" loctite that I might still be able to muscle off if needed using a bolt puller arrangement? Alternatively, the bearings are captured in the pulley on both sides by snap rings. I could leave off the snap ring on the righthand side, so that if I need to remove this pulley the pulley itself would slide off, leaving the bearings on the shaft where I can get some heat or solvent on them.

The attached photo shows the arrangement (minus the snap rings) on the left and right sides of the bearings.