Peter S

Diamond

- Joined

- May 6, 2002

- Location

- Auckland, New Zealand

Maybe this has been posted before? A good one from Shorpy:

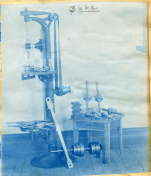

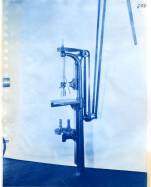

1902. "Screw Machine Department, National Cash Register, Dayton, O

www.shorpy.com

www.shorpy.com

1902. "Screw Machine Department, National Cash Register, Dayton, O

Shorpy Historical Picture Archive :: Screw Department: 1902 high-resolution photo

Vintage photographs available as fine-art prints or digital stock images