dandrummerman21

Stainless

- Joined

- Feb 5, 2008

- Location

- MI, USA

Sorry for the terrible title, I wasn't sure how to explain it in a few words.

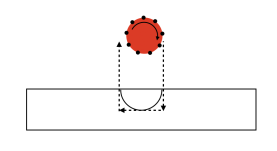

So I have a part that has a woodruff key cut into it, and I wanted to use cutter comp to adjust the depth. The tool is a woodruff keycutter, and I am plunging straight into the shaft in the Y direction.

I thought this was possible but the machine doesn't move as expected and I didn't see a relavent parameter.

Here is my code:

G0G55X1.38Y-.85S300M3

G43H5Z.1M8

G1Z-.4365F50

G1G41D5Y-0.506F1.5 (I want this to go further with a cutter comp adjustment)

G4X1

G40G1Y-.85F20.

G0Z5.M9

So If i put in a -.005 value in for cutter comp, it will move over .005" in X over the length of the move. Since the next movement is straight back out in Y, I expected it to not move sideways but instead go further in Y only.

I tried removing the dwell and having the next block be a Y move but it did not work.

Is this possible? Or am I stuck doing it other ways (such as modifying code, or using macro variables in my program)

So I have a part that has a woodruff key cut into it, and I wanted to use cutter comp to adjust the depth. The tool is a woodruff keycutter, and I am plunging straight into the shaft in the Y direction.

I thought this was possible but the machine doesn't move as expected and I didn't see a relavent parameter.

Here is my code:

G0G55X1.38Y-.85S300M3

G43H5Z.1M8

G1Z-.4365F50

G1G41D5Y-0.506F1.5 (I want this to go further with a cutter comp adjustment)

G4X1

G40G1Y-.85F20.

G0Z5.M9

So If i put in a -.005 value in for cutter comp, it will move over .005" in X over the length of the move. Since the next movement is straight back out in Y, I expected it to not move sideways but instead go further in Y only.

I tried removing the dwell and having the next block be a Y move but it did not work.

Is this possible? Or am I stuck doing it other ways (such as modifying code, or using macro variables in my program)

It's not designed to do that.

It's not designed to do that.